BASIC INFO

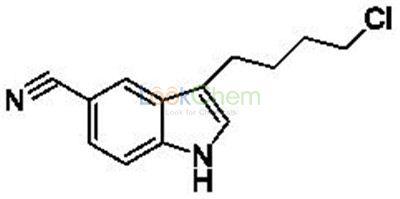

BCND family catalyst is a new generation high-efficiency polypropylene catalyst and has proprietary intellectual property rights.

This family catalyst has three kinds of catalyst, they are BCND-I, BCND-II, and BCND-III. Different catalyst has a different hydrogen responsibility.

Technology characteristic

1)New type internal donor technology is used, and DNBP compound is not existed.

2)High activity, it is more than 60,000g PP/g Cat.(Condition: 51 reactor, polymerization temperature is 70℃, reacted time is 2 hours, distributed pressure of H2 is 0.2MPa.)

3)Good isotacticity and adjustable.

4)Broaden molecular weight distribution, and the polymer has a good machining performance.

5)The polymer has a good morphology and fewer fines.

6)Different hydrogen responsibility can be supplied.

Applicable process

This kind of catalyst can be used in Hypol, Novolen, Unipol, Innovene and spheripol process, and can produce homo-polymer, impact copolymer and random copolymer.

Industrial applications

BCND family catalysts have a high activity and broaden molecular weight distribution, and can be used to produce PPR, BOPP, high MFR injection molding polymer. The polymer has a good comprehensive performance and machining performance.

BCND family catalyst has a good co-polymerization performance, and distribution of ethylene chain is homogeneous. When produce random co-polymer, we can get lower melting point PP or more transparent PP in the same ethylene content. When produce impact co-polymer, we can produce PP which contain higher rubber content in the same polymerization condition.

Packaging. Storage and Transport

Packaging can be supplied in dry catalyst or oil catalyst.

Dry catalyst packaging: BCND dry catalyst is packaged in zinc-plated steel drums under nitrogen protection, and contains 40kgs or 80kgs every drum.

Oil catalyst packaging: Dry catalyst is mixed proportionally with white oil. The mixture is under nitrogen blanket special drums. In transportation, the catalyst should be handled carefully avoiding bumping, opening of cover or contacting with air. It should be stored in a dry, clean and ventilated space out of direct sunlight.

Notice before being used:

The catalyst should be laid under the environment with the temperature about 15℃ more than 24hours, and roll the drum more than 24 hours before being used.