BASIC INFO

DQC family catalyst uses the carrier which is creative and prepared by a new process. Comparison with the similar catalyst, the comprehensive performance is improved obviously.

Technology characteristic

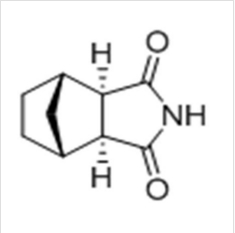

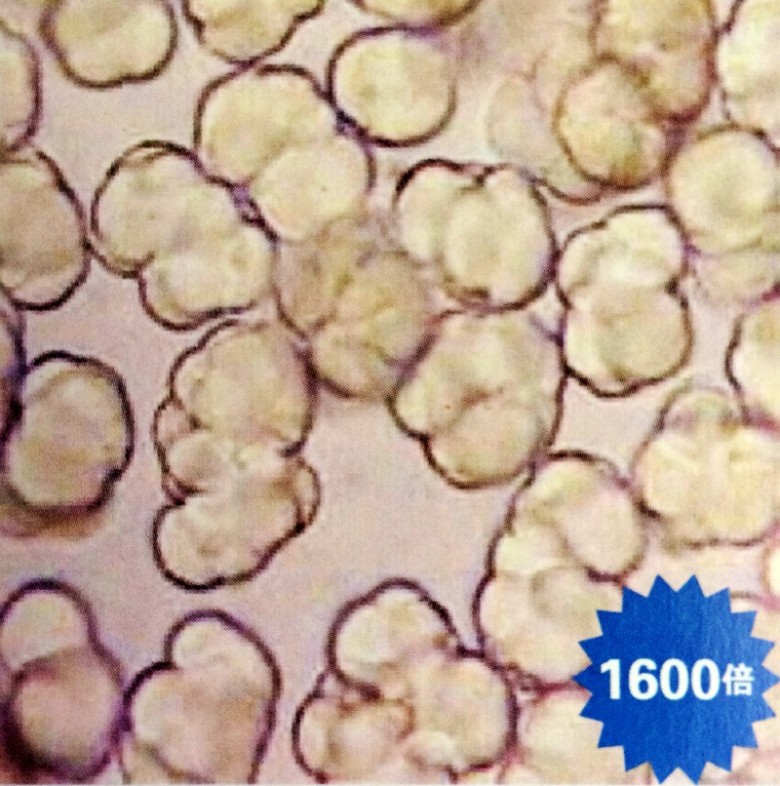

1) Particle size distribution of catalyst is centralized, and the particle size is controllable and adjustable.

2) Catalyst activity is more than 5.0X104 g-PP/g-Cat.(Condition: 51 reactor, polymerization temperature is 70℃, reacted time is 2 hours, distributed pressure of H2 is 0.2MPa.)

3) Excellent hydrogen responsibility.

4) The polymer has a good isotacticity, and the isotacticity index is adjustable.

5) This kind of catalyst has an excellent copolymerization performance, and is suitable to produce the high rubber content polymer.

6) Polymer particle is spherical, and has good morphology, and less fines.

Applicable process

This kind of catalyst is suitable to use in Spheripol-I process, spheripol-II process and ST process. It is widely used to produce homo-polymer, impact copolymer, random copolymer and three units copolymer.

Industrial applications

DQC301 catalyst has smaller particle size, ad is suitable to use in single spheripol process and can be used to produce homo polymer.

DQC401 catalyst belongs to general type PP catalyst, is suitable to use in single spheripol process, double spheripol process, ST and gas phase process, can be used to produce homo-polymer, impact copolymer, random copolymer.

DQC602 catalyst is suitable to produce impact copolymer and three units’ copolymer.

DQC family catalyst is widely used in Spheripol-I process, spheripol-II process and ST process and is more than 30 suites plants distributed in China and other countries. The products has homo polymer, impact copolymer, ethylene-propylene random copolymer, propylene-butene random copolymer, and ethylene-propylene-butene random copolymer, and have a good performance.

Packaging. Storage and Transport

DQC family catalyst is packaged in zinc-plated steel drums under nitrogen protection, and contains 40 or 80kg every drum. In transportation, the catalyst should be handled carefully avoiding bumping, opening of cover or contacting with air. It should be stored in a dry, clean and ventilated space out of direct sunlight.